The Fact About gearbox cvt That No One Is Suggesting

The Fact About gearbox cvt That No One Is Suggesting

Blog Article

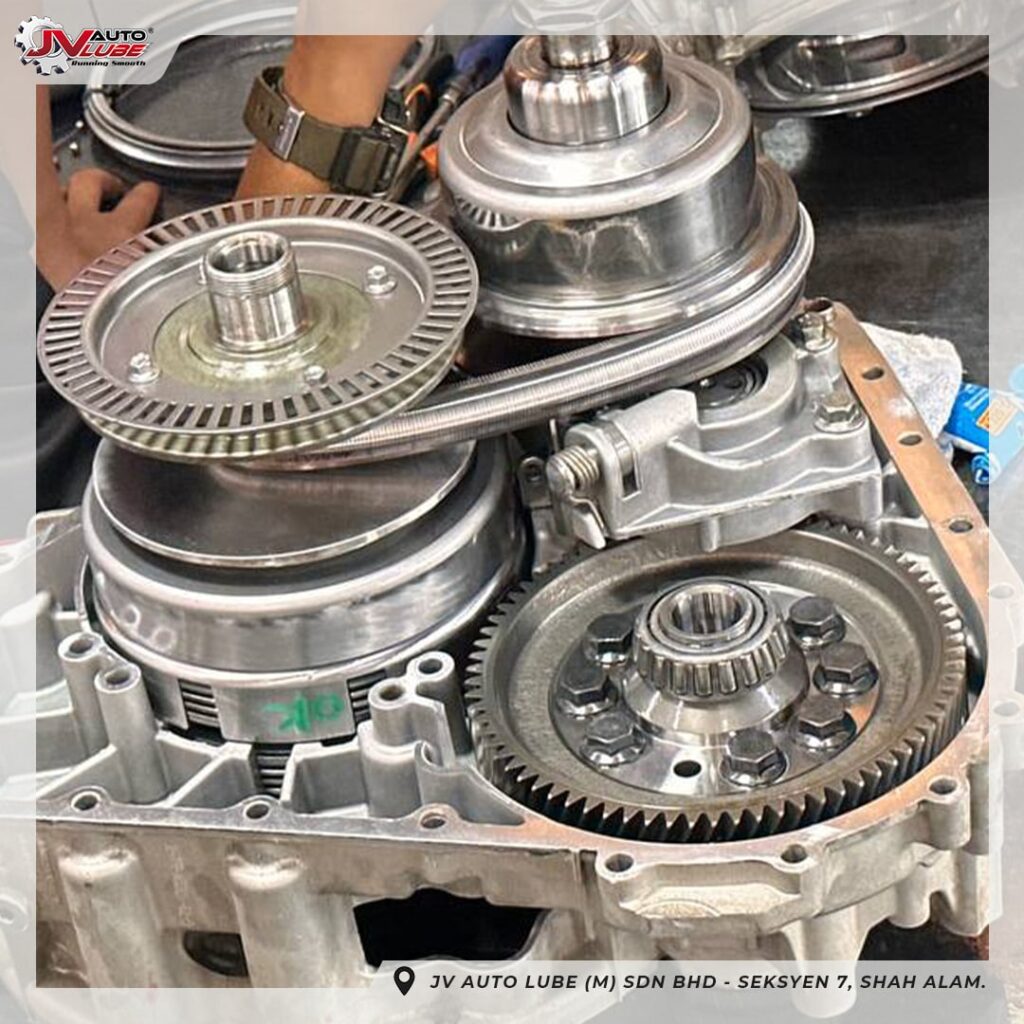

A continually variable transmission (CVT) is often a variety of automated transmission which has been attaining reputation lately. Compared with common computerized transmissions that utilize a established quantity of gears, CVTs utilize a belt and pulley technique that provides an infinite quantity of gear ratios.

On the list of most important disadvantages of CVTs is that they can sometimes feel unresponsive or sluggish when accelerating from a stop. This is because the transmission normally takes time to adjust the pulleys and belt to the correct ratio to the engine’s power output.

Positively Infinitely Variable (PIV) chain drives are unique in which the chain positively interlocks Along with the conical pulleys. This is certainly obtained by getting a stack of many modest rectangular plates in each chain url that can slide independently from aspect-to-facet. The plates might be rather slender, all-around a millimeter thick. The conical pulleys have radial grooves. A groove on just one aspect with the pulley is fulfilled with a ridge on one other facet and And so the sliding plates are pushed back and forth to conform towards the sample, successfully forming enamel of the correct pitch when squeezed amongst the pulleys.

The cost of repairs for Honda CVT transmission challenges will vary depending on various variables, like guarantee protection, recalls, and also other prospective assistance solutions. In case your car is still underneath the company’s warranty, Honda ordinarily addresses the expense of repairs or substitution.

In this article, we reveal the rules of the CVT gearbox and why it is now so popular among automakers.

These are typically conical pulleys with site oficial variable diameters. The motor powers the enter pulley whilst the output pulley sends electric power towards the wheels by means of both a driveshaft or CV shafts.

Higher body weight. As a result of large oil tension at which a hydrostatic CVT operates, the pump and motor(s) are under sizeable mechanical worry, particularly when maximum electric power and loading is becoming used.

A belt-driven structure presents approximately 88% performance,[four] which, while decreased than that of the guide transmission, might be offset by enabling the motor to operate at its most productive RPM regardless of the car's pace.

• Driving a motor vehicle by using a CVT is an extremely various encounter and many motorists not to like it as you will not sense the engine accelerating; you do not feel any shifts in its place you are feeling the engine racing as it will having a slipping clutch or possibly a failing transmission which happens to be just the CVT adjusting to supply best electric power.

The end result is really a smoother, additional effective and more rapidly generate than an ordinary computerized. There's a draw back though, and that’s the Electricity losses due to friction are better by using a CVT – about 5 to 15% dependant upon the form, While with usual gears it’s far more like 2-5%. As ever, progress is closing the hole, and the fact the CVT enables the engine to remain in its optimum rev improvements greater than compensates for the additional performance loss.

It very same as set input pulley but unlike preset input shaft this shaft is placed on the remaining-hand facet above the output shaft.

Action: This type of noise normally demands fast awareness from a specialist mechanic. Driving by using a clunking transmission can cause more hurt and likely lead to a complete transmission failure.

The trick is, so as to keep belt stress, the two pulleys must act oppositely in unison. I assume only one pulley really should be actively different, whilst another can benefit from spring rigidity to shut the gap So keeping pressure.

when the vehicle requirements pace ratios, the feeding conical pulley (sheave) above the input shaft moves in direction of the mounted pulley which consequently shifts the Element of v-formed belt wrapped around the enter pulleys to the bigger cross-sectional Element of the conical enter pulleys.